Firefighting

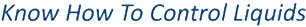

With its “Audoli&Bertola” Division, Gruppo Aturia operates in the fire-fighting field by supplying pumping units that comply with European Standards (EN 12845 and EN 12259-12) and the US standard (NFPA 20).

Audoli&Bertola’s technical expertise allows to easily operate in civil and industrial sectors and comply with the strictest specifications required by refineries, petrochemical industries, off-shore infrastructures, platforms and in-shore infrastructures. Audoli&Bertola has developed a range of products for explosive risk areas: many products have been made with diesel and gas engines,

suitable to operate in EExd II B or C Atex areas. Gruppo Aturia can supply an extensive range of centrifugal pumps for fire-fighting services, both with a vertical and a horizontal design. Audoli&Bertola is the only Pump Manufacturer in Italian that was given Factory Mutual’s approval for:

- Vertical Pumps: from 500 USGPM to 4000 USGPM, at 50 and at 60 Hz.

- Split Case Pumps: from 750 USGPM to 2000 USGPM, at 50 and at 60 Hz.

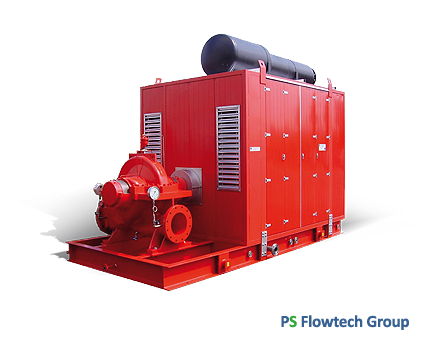

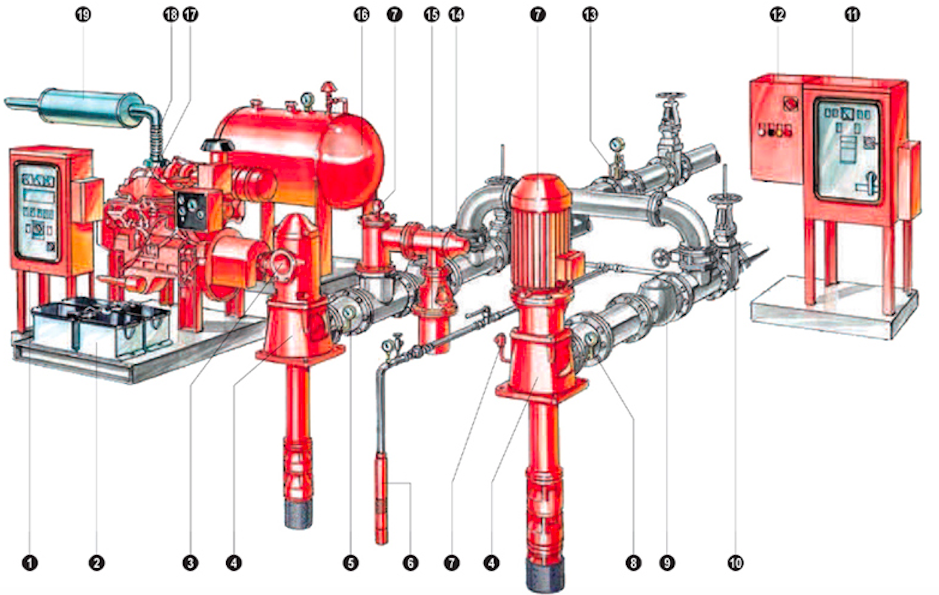

1. Typical installation of fire-fighting units with horizontal split-case pumps

FM Approved horizontal split-case type centrifugal fire pumps are relatively simple to operate and repair. These pumps have a two-part casing divided in a horizontal plane through the shaft center line. They are well suited to fire protection service where a water supply is obtainable under a positive head.

|

|

1_Diesel engine fire pump controller / 2_Batteries / 3_Jockey pump / 4_Concentric discharge increaser / 5_Enclosed discharge overflow cone / 6_Eccentric suction reducer / 7_Suction pressure gauge / 8_Horizontal pump / 9_Circulation relief valve / 10_Electric motor / 11_Check valve / 12_OS& Y gate valve / 13_Electric motor fire pump controller / 14_Jockey pump controller / 15_Tlow est fmeter / 16_Automatic air release valve / 17_Main relief valve / 18_Discharge pressure gauge / 19_Fuel tank / 20_Diesel engine / 21_Flexible exhaust connector / 22_Exhaust muffler

|

2. Typical installation of fire-fighting units with vertical turbine pumps

Vertical shaft, turbine type centrifugal fire pumps have submerged impellers contained in a series-bowl assembly at the bottom of a vertical shaft. The design is similar to pumps used extensively for industrial and municipal service. These pumps are FM Approved for discharging water from lakes, streams, open sumps, drilled wells and other equivalent subsurface sources. Each pump consists of a discharge head, motor stand, column pipe, line shaft, bowl assembly and suction strainer. For electric drive, FM Approved pumps must be used with a vertical, electric motor. For internal-combustion-engine drive, FM Approved pumps must be connected to the FM Approved engine through an FM Approved right-angle gear drive.

|

|

1_Diesel engine fire pump controller / 2_Batteries / 3_Right angle gear / 4_Vertical turbine pump 5_Discharge pressure gauge / 6_Jockey pump / 7_Automatic air release valve / 8_Concentric discharge increaser / 9_Check valve / 10_OS& Y gate valve / 11_Electric motor controller / 12_Jockey pump controller / 13_Test flow meter / 14_Main relief valve / 15_Open discharge overflow cone / 16_Fuel tank / 17_Diesel engine / 18_Flexible exhaust connection / 19_Exhaust muffler

|